[ad_1]

After large excavators could not clear the rubble blocking an under-construction tunnel in Uttarkashi where 40 workers are trapped, rescuers are now using a “trenchless” technique, putting together passages made of mild steel pipes right through the debris so the men can crawl out.

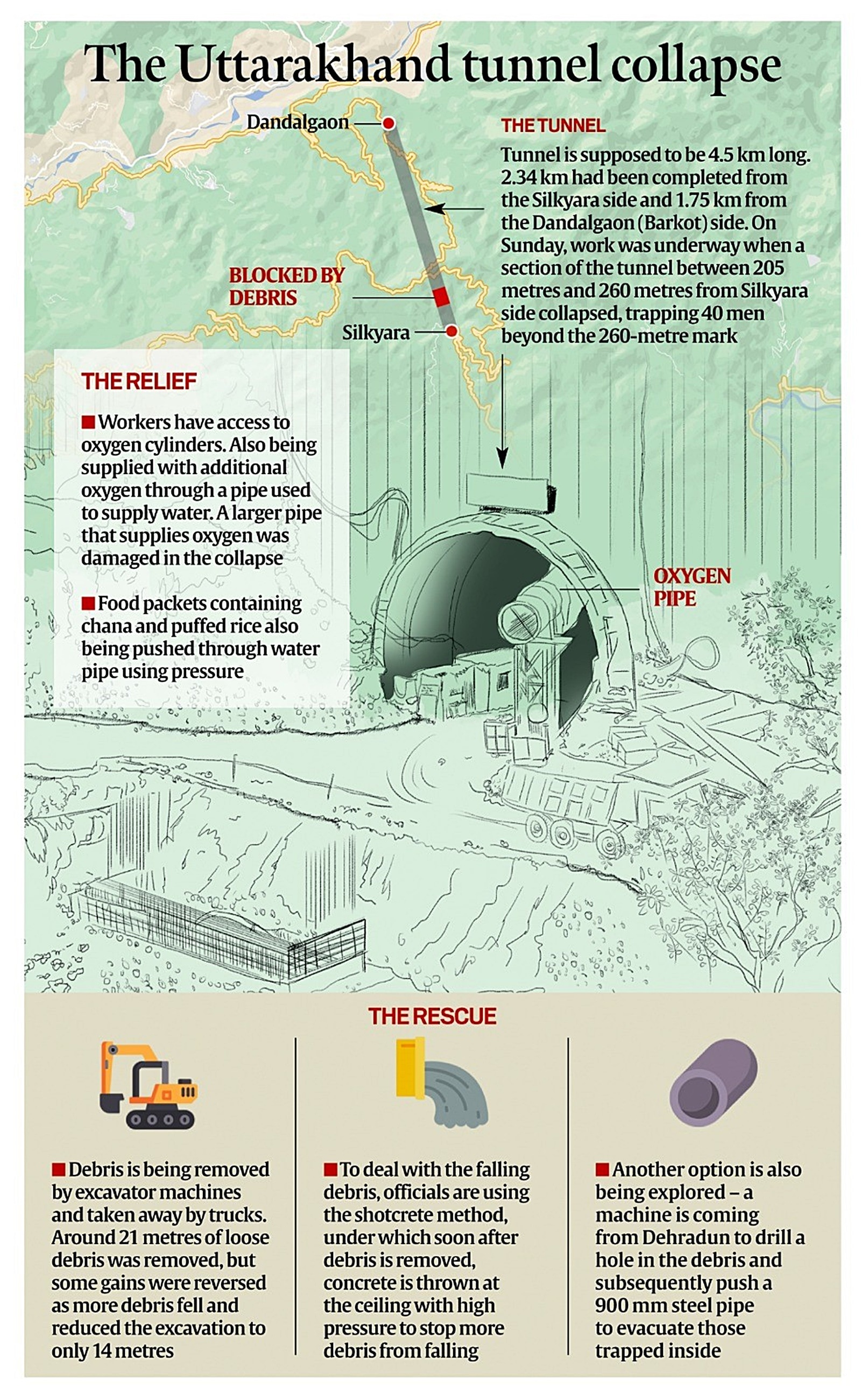

It was around 5.30 am on Sunday that the under-construction tunnel on the Yamunotri National Highway, meant to connect Silkyara and Dandalgaon in Uttarakhand’s Uttarkashi district, collapsed.

Rescue and relief operations underway after a portion of a tunnel under construction between Silkyara and Dandalgaon on the Brahmakhal-Yamunotri national highway collapsed, in Uttarakhand’s Uttarkashi district. (PTI)

Rescue and relief operations underway after a portion of a tunnel under construction between Silkyara and Dandalgaon on the Brahmakhal-Yamunotri national highway collapsed, in Uttarakhand’s Uttarkashi district. (PTI)

According to a statement issued by the state government, consultations are being held with experts of the National Highways Authority of India, Rail Vikas Nigam Limited, National Housing and Construction Limited, L&T, Tehri Hydro Development Corporation, Border Roads Organisation, and National Highways & Infrastructure Development Corporation Ltd.

In the first two days, the plan to remove debris using heavy excavator machines, and prevent more debris from falling using the “shotcrete method”, has only been partially successful. Under shotcreting, as soon as debris is removed, concrete is shot at high pressure to prevent more from falling.

Along with this, on the advice of the experts, efforts were being made to prepare a safe passage to reach the trapped laborers by removing the debris and installing setting plates, but more debris that kept falling from the upper part of the tunnel hampered the plan.

Under the new plan, the “trenchless” technique is being used to create a passage through 900 mm wide mild steel (MS) pipes. An auger machine, which consists of a helical screw blade known as an auger, attached to a rotating shaft, is already inside the tunnel. On Tuesday evening, construction and priming work of the platform of the auger drilling machine was being completed, and other equipment was being assembled on the frame.

The basic principle behind its operation involves a spiral blade rotating and pushing material away from the hole being drilled. Once drilled, the MS pipes can be pushed through the pile of debris, creating a passage wide enough for those inside to crawl through.

In total, eight pipes of 900 mm and 11 pipes of 800 mm are at the site.

Most Read

The “trenchless” techniques can be valuable in tunnel collapse rescue operations to access and rescue individuals trapped underground without exacerbating the collapse or causing further harm. These methods offer a way to reach trapped individuals without significant excavation, reducing the risk of further structural instability. A team of five expert engineers from the Irrigation Department reached the incident site from Dehradun for the installation of MS pipes.

It was around 5.30 am on Sunday that the under-construction tunnel on the Yamunotri National Highway, meant to connect Silkyara and Dandalgaon in Uttarakhand’s Uttarkashi district, collapsed. (Credits: Mithun Chakraborty)

It was around 5.30 am on Sunday that the under-construction tunnel on the Yamunotri National Highway, meant to connect Silkyara and Dandalgaon in Uttarakhand’s Uttarkashi district, collapsed. (Credits: Mithun Chakraborty)

Meanwhile, a staging area has been created at the site, where vertical drill machines, horizontal drill machines, and shotcrete machines are available. Three poclain machines, two JCBs, six trucks, one hydra, and two loaders are deployed outside the tunnel, while four poclain machines, three shotcrete machines, two boomers, two hydras, and two trucks are working inside.

The Uttarakhand government has also formed an expert committee under the director, Uttarakhand Landslide Mitigation and Management Center, to study and investigate the causes of the collapse. The committee includes experts from Wadia Institute of Himalayan Geology, Indian Institute of Technology, Central Building Research Institute, and the Geological Survey of India.

[ad_2]

While officials say the men are safe – communication has been established via walkie-talkies and they are being supplied food and oxygen via a pipe meant to supply water – two and a half days have elapsed since they got trapped.

While officials say the men are safe – communication has been established via walkie-talkies and they are being supplied food and oxygen via a pipe meant to supply water – two and a half days have elapsed since they got trapped.